- About

- Services

Collaborative planning and execution

Working hand-in-hand with your team, Malone Group assists in planning and executing your project from its conceptual stage to commissioning. Our goal is to ensure timely completion within budget, prioritizing safety compliance throughout the process.

Comprehensive range of design services

Your capital project will benefit from our comprehensive range of engineering design services, including feasibility studies, outline designs, budget costing, detail designs/full specifications and tendering packages.

Delivering Zero Harm in all environments

Our team provides class leading safety management services, driven by the close integration between our safety and engineering departments.

Using less resources for the same output without compromising on quality

Our engineers design solutions that minimise energy and water consumption using both established technologies and and new innovative solutions.

Simplified, practical and cost effective solutions

We automate processes to enable data collection, as a key step towards digital transformation. Employing a range of competencies across the group we generate practical, budget conscious transformation roadmaps that we can then implement. This is a key step towards being a factory of the future or even just a better manufacturing space for today.

Connecting the parts to work together automatically

Automating production and process environments provides many benefits. Utilizing the experience and expertise of our teams, we manage the delivery of automation solutions; from obsolescence assessments to system design (PLC, SCADA, HMI etc.), integration to commissioning.

- Capabilities

Optimised for performance, safety, and sustainability

The Built Environment encompasses commercial, retail, medical, and educational buildings and manufacturing sites It’s where, we as engineers, bring life to architectural concepts, designing systems to make the spaces functional, workable and livable. Our practicality and expertise shines brightly, crafting environments that resonate with efficiency, sustainability, and innovation.

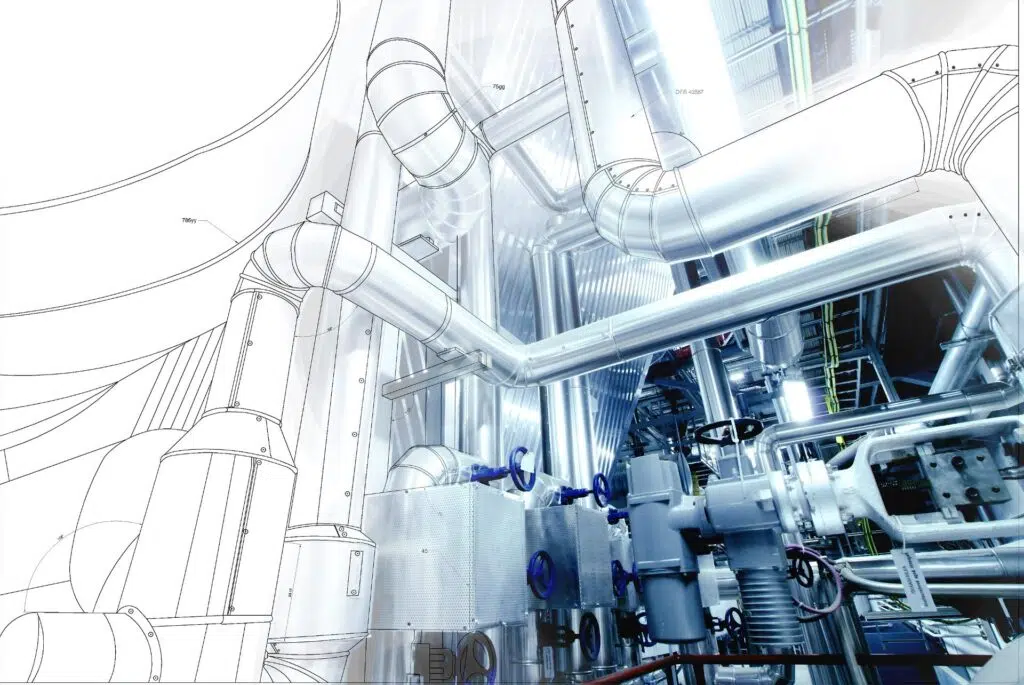

Engineering marvels meet practical application

Manufacturing Facilities are not just buildings, they are the cradle of innovation, where engineering marvels meet practical application. We appreciate that each facility is a unique entity, a bespoke blend of technology, human skill, and process. This understanding is the bedrock upon which we offer our services, ensuring that each customer’s facility is not only built to last but also to evolve.

Mastering the core operations that drive productivity

Inside the Process delves deep into the heart of manufacturing and production processes, uncovering the layers and intricacies that make industries tick. We stand as a guiding light in this complex domain, wielding expertise and innovation to optimize and enhance every step.

It is bridging the gaps between isolated processes

Connecting the Process is a crucial aspect that harmonises the various segments of production, operations, and management to create a seamless flow. This capability is about bridging the gaps between isolated processes, ensuring that every step from inception to delivery is interconnected and efficient. In the vast tapestry of industry, Connecting the Process serves as the thread that weaves through each operation, enhancing communication, data flow, and operational synergy. Malone Group, with its profound expertise and innovative solutions, is at the forefront of making these connections tangible and effective.

Engineering marvels meet practical application

Welcome to our forward-thinking approach to embedding sustainability at the heart of today’s operations and projects. In a world where the environment and sustainability are not just concerns but imperatives, A Sustainable Now represents our commitment to creating solutions that meet the needs of the present without compromising the ability of future generations to meet their own needs. This vision encompasses a broad spectrum of practices, from reducing carbon footprints and enhancing energy efficiency to promoting renewable resources and sustainable development.

Enhancing precision, efficiency, and engagement

Looking to the Future is a concrete approach to integrating advanced technologies into the fabric of engineering, design, and project management. This forward-looking vision encompasses Augmented Reality (AR), Virtual Reality (VR), and 3D Modeling, technologies that are revolutionizing the way we visualize, interact with, and understand complex processes and environments. Malone Group is at the forefront of this revolution, leveraging these technologies to provide innovative solutions that enhance precision, efficiency, and engagement in a wide range of industries.

- Projects